Researchers at the University of Texas have designed a micro-windmill that generates wind energy and may become an innovative solution to cell phone batteries constantly in need of recharging as well as home energy generation where large windmills are not preferred.

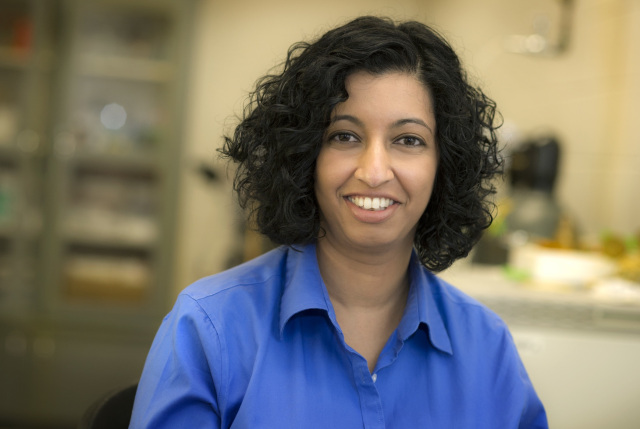

Doctoral researcher Smitha Rao and Professor of Electrical Engineering J.C. Chiao designed and built the device that is about 1.8 mm at its widest point. A single grain of rice could hold about 10 of these tiny windmills. Hundreds of the windmills could be embedded in a sleeve for a cell phone. Wind, created by waving the cell phone in air or holding it up to an open window on a windy day, would generate the electricity that could be collected by the cell phone’s battery.

“Imagine that they can be cheaply made on the surfaces of portable electronics,” Chiao said, “so you can place them on a sleeve for your smart phone. When the phone is out of battery power, all you need to do is to put on the sleeve, wave the phone in the air for a few minutes and you can use the phone again.”

Chiao said because of the small sizes, flat panels with thousand of windmills could be made and mounted on the walls of houses or building to harvest energy for lighting, security or environmental sensing and wireless communication.

The micro windmills were tested successfully in September 2013 in Chiao’s lab. The windmills operate under strong artificial winds without any fracture in the material because of the durable nickel alloy and smart aerodynamic design.

Smitha Rao’s works in micro-robotic devices initially attracted the interest of WinMEMS Technology –a Taiwanese company well know for sophisticated MEMS (Micro-Electrical-Mechanical-Systems). They asked Rao and Chiao to brainstorm over novel device designs and applications for the company’s unique fabrication techniques, which are known in the semiconductor industry for their reliability.

“The company was quite surprised with the micro-windmill idea when we showed the demo video of working devices,” Rao said. “It was something completely out of the blue for them and their investors.”

Rao’s designs blend origami concepts into conventional wafer-scale semiconductor device layouts so complex 3-D moveable mechanical structures can be self-assembled from two-dimensional metal pieces utilizing planar multilayer electroplating techniques that have been optimized by WinMEMS.

Rao, who earned her Ph.D in 2009 said. “I think we’ve only scratched the surface on how these micro-windmills might be used.” The micro-windmills can be made in an array using the batch processes. The fabrication cost of making one device is the same as making hundreds or thousands on a single wafer, which enables for mass production of very inexpensive systems.

(Link UTA )