How much power from MEMS windmills?

January 20, 2014 // Peter Clarke

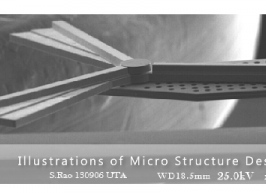

A University of Texas Arlington research team has enjoyed considerable publicity for its development of a MEMS windmill that the developers have said could, when produced in array, provide energy for a mobile phone or be used for home energy generation.

But is that reasonable?

The one thing that is conspicuous by its

absence from any of the photographs or the Youtube video of the prototype MEMS

windmill, is any electrical wiring. Similarly conspicuous by its absence from

the UT Arlington website posting, is any discussion of how much electrical power

could be drawn from a millimeter-scale windmill.

In fact it is a general

consideration that the efficiency of conversion from wind to electrical power

increases the larger the system. Hence the desire to create wind turbines that

are hundreds of feet high. So how efficient would an array of thousands of

millimeter-scale windmills be? Would it be practical as a source of significant

amount of electrical energy?

Nonetheless Smitha Rao and J.-C. Chiao at UT

Arlington have designed and built a windmill that is about 1.8-mm at its widest

point using a recently formed foundry, WinMEMS Technologies Co. Ltd. (Guishan,

Taiwan). The blades are made from nickel alloy using planar multilayer

electroplating techniques.

"The problem most MEMS designers have is that

materials are too brittle,” Rao said, in a statement on the website. MEMS are

typically made from silicon. The micro windmills were tested in September 2013

and operate under "strong artificial winds" without any fracture in the material

because of the durable nickel alloy and smart aerodynamic design, according to

UT Arlington.

WinMEMS likes the idea and has struck an agreement with UT Arlington whereby the university gets to hold the intellectual property while WinMEMS is licensed to explore commercialization opportunities.

It is clear that MEMS windmills could be easy to make at the wafer scale and could be produced in very thin redundant structures.

Researcher Chiao said that flat panels with thousand of MEMS windmills could be mounted on the walls of buildings to harvest energy for lighting, security or environmental sensing and wireless communication.

There may be some issues about the most efficient MEMS structure and its orientation within a wall-mounted panel – where the wind passes over the surface rather than through it – but such a discussion can only be had in the context of how much electrical power can be drawn from the system.

Related links and articles:

News articles:

Ten analog, MEMS and sensor startups to watch in 2014

Startup offers chip-scale solar energy harvester

Singapore, Abu Dhabi, agree to develop MEMS together

All news.jpg) Business News

Business News

More funds for SiC-on-silicon power technology

February 03, 2014

Martin Lamb has been appointed as the Chairman of Coventry-based Anvil Semiconductors Ltd, to lead the company's commercialization ...

- Market News

Sales record ends chip industry's year

- Technology News

Design guide supports high speed COM Express signals

- Technology News

Samsung to reveal tablet with10-inch AMOLED at MWC 2014?

- Business News

Five lessons from Lenovo’s Motorola deal

.jpg) Feature Articles

Feature Articles

3D IC ramp up: what can we learn from MEMS?

February 03, 2014

Under the motto “Application Ready”, this year’s 3D TSV Summit was very much focused on how to make 3D IC design an attractive ...

- Technology News

Researchers make magnetic monopoles

- Feature Articles

MediaTek goes wearable, Chinese and cheap

- Business News

Distributor MSC Technologies to operate as part of Avnet

Technical papers

- Understanding WLAN offload in cellular networks

- Software-Defined Radio Handbook

- High Efficiency, 150V 100mA Synchronous Step-Down Regulator

- Solutions for LTE-Advanced Manufacturing Test – Understanding the Requirements for LTE

Filter Wizard

READER OFFER

Read more

To offer you a good start in 2014, Renesas Electronics Europe is giving away four demonstrations kits worth 325 Euros each, for EETimes Europe's readers to win.

Designed as an evaluation and demonstration tool for the company’s RX62N microcontrollers, the RX62N RSK (part number R0K5562N0S000BE) provides users with a powerful debug and demonstration platform targeted at common...

Read moreDesign centers

Automotive

December 15, 2011 | Texas instruments | 222901974

Unique Ser/Des technology supports encrypted video and audio content with full duplex bi-directional control channel over a single wire interface.

More funds for

SiC-on-silicon power technology

More funds for

SiC-on-silicon power technology Sales record

ends chip industry's year

Sales record

ends chip industry's year Design guide

supports high speed COM Express signals

Design guide

supports high speed COM Express signals Samsung to

reveal tablet with10-inch AMOLED at MWC 2014?

Samsung to

reveal tablet with10-inch AMOLED at MWC 2014? Five

lessons from Lenovo’s Motorola deal

Five

lessons from Lenovo’s Motorola deal Researchers make magnetic monopoles

Researchers make magnetic monopoles  MediaTek goes wearable, Chinese and cheap

MediaTek goes wearable, Chinese and cheap Distributor MSC Technologies to operate as part of Avnet

Distributor MSC Technologies to operate as part of Avnet What technologies to watch for in 2014? – Part 1

What technologies to watch for in 2014? – Part 1 European

buses steer towards zero emission fuel cells

European

buses steer towards zero emission fuel cells E-whiskers

could turn robots hairy

E-whiskers

could turn robots hairy JM

Energy invests $60m in high-volume LIC production

JM

Energy invests $60m in high-volume LIC production 4.8-inch AMOLED ultra-thin smartphone hits the streets

4.8-inch AMOLED ultra-thin smartphone hits the streets Kaneka inks

OLED technology license deal

Kaneka inks

OLED technology license deal

Follow us