A University of Texas at Arlington research associate and an electrical engineering professor have designed a micro-wind turbine that generates power and may become an unusual solution to charging cell phone batteries and other small, wireless, or remote sensing devices.

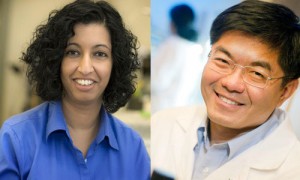

Smitha Rao and J.C. Chiao have designed and built the device with a rotor diameter of 1.8 mm. Professor Chiao would not say exactly how the small devices produce power but did say there were about three methods for doing so.

One suggested application would place many tiny turbines in a sleeve for a cell-phone charger. Wind, created by waving the cell phone in air or holding it in a breeze, would generate the electricity collected by the cell phone’s battery.

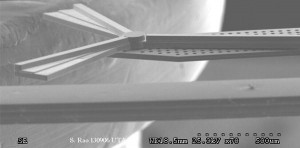

The scanning electron microscope image of the blades shows a stepped profile that produces rotation with airflow.

Rao’s work in micro-robotic devices initially heightened a Taiwanese company’s interest in having Rao and Chiao brainstorm novel device designs and applications for the company’s unique fabrication techniques, recognized by the semiconductor industry for their reliability and precision. Chiao says the axel and latch, the smallest details on the turbine, could not be made smaller for the rotor to turn freely. These governed other dimensions.

“The interested company, WinMEMS Technolgoies, was quite surprised with the micro-windmill idea when we showed the demo video of working devices,” Rao said. “It was something completely out of the blue for them and their investors.”

“The micro-windmills work well because the metal alloy is flexible and Smitha’s design follows minimalism for functionality,” says Chiao. The design goal was to produce a small, cheap, yet durable turbine. It will be produced using semiconductor manufacturing methods, so the cost for one or 1,000 is the same. And if one fails, there are many more that keep working. “However, I think we’ve only scratched the surface on how these micro-windmills might be used,” says Chiao.

Rao’s designs blend origami concepts into conventional wafer-scale semiconductor device layouts so complex 3D moveable mechanical structures can be self-assembled from 2D metal pieces using planar multilayer electroplating techniques that have been optimized by WinMEMS Technologies.

The micro windmills were tested successfully in September 2013 in Chiao’s lab. The devices operated under a strong air flow without material fractures thanks to the durable nickel alloy and smart aerodynamic design.

Chiao said because of the small sizes, flat panels with thousand of windmills could be made and mounted on the walls of houses or building to harvest energy for lighting, security, or environmental sensing and wireless communication.

Company representatives visited with the UT Arlington team several times in 2013 to discuss collaboration. An agreement has been established for UT Arlington to hold the intellectual properties while WinMEMS explores commercialization opportunities. UT Arlington has applied for a provisional patent. For a brief video showing the blades spinning, visit: http://www.winmemstech.com/en/page/custom68/

The University of Texas at Arlington

http://www.uta.edu/

Speak Your Mind Cancel reply